Welcome to Zhongxin Iron and Steel (Shandong) Group Co., Ltd.

Tel : +86-17362202101 Email:sales09@zxjtsteel.com

PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

410 410S Stainless Steel Coil

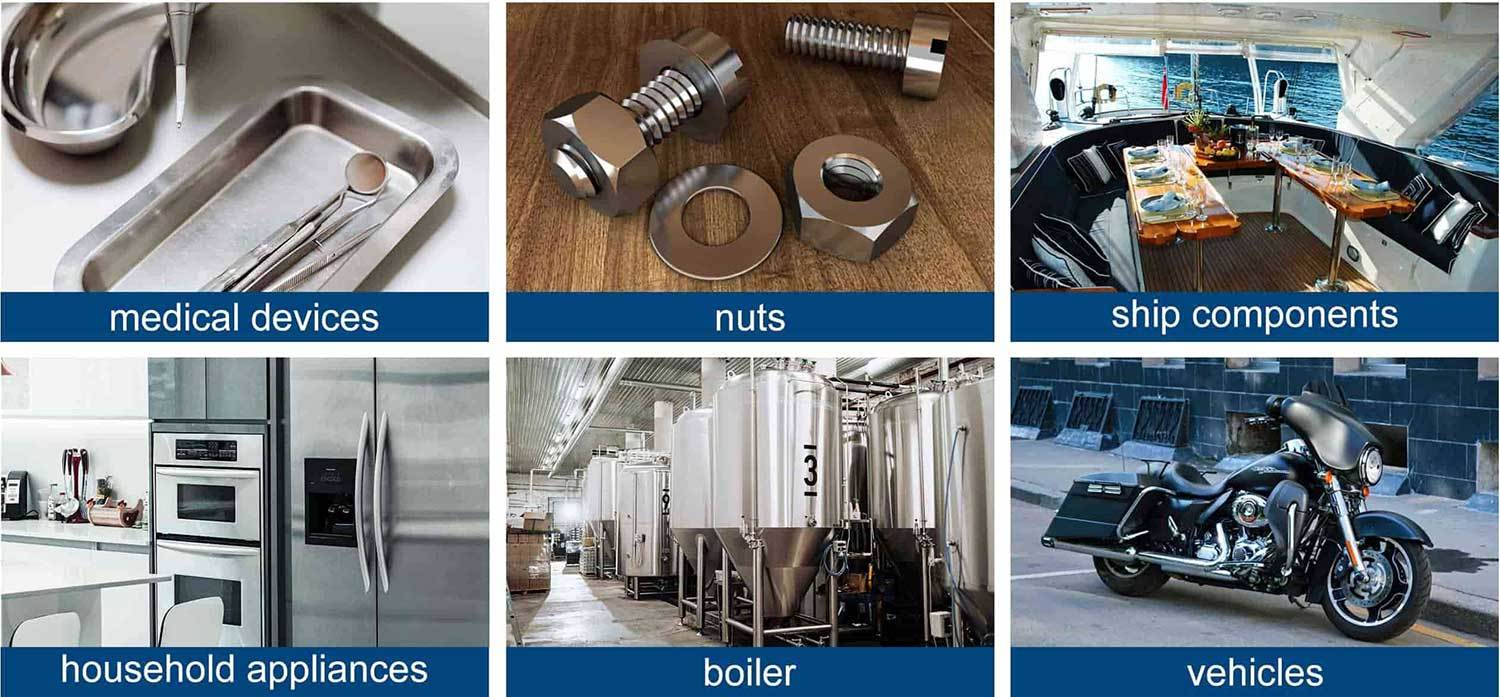

Characteristics of 410 410S Stainless Steel Coil: 1) High strength; 2) Excellent machinability 3) Hardening after heat treatment; 4) Magnetic; 5) Not suitable for harsh corrosive environment. 3. Scope of application General blade, mechanical parts, class 1 tableware (spoon, fork, knife, etc.).

410 410S Stainless Steel Coil Strip Specifications:

|

Grades |

Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L , 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

|

Thickness |

0.2mm - 60mm |

|

Width |

3.2mm - 2000mm |

|

Length |

AS PER CUSTOMER'S REQUIREMENT |

|

Type of Material |

STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD,FULL HARD. |

|

Finish |

NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

|

Standard |

ASME, ASTM, AISI, EN, BS, GB, DIN, JIS, SUS, etc. |

|

manufacture |

Cold Rolled ,hot rolled |

|

Application |

Decoration,Industry,food processing and medical industry ,ships building industry etc. |

|

Certification |

SGS, BV, IQI, TUV, ISO, CE, etc |

|

Coil Weight |

3-10 Tons Or As Your Requirements |

|

Tolerance |

±1% |

|

MOQ |

1 ton |

|

Supply Ability |

5000 tons / month |

|

Lead Time |

7-15 working days after the receipt of 30% deposit |

|

Payment Terms |

30%T/T Advance + 70% Balance |

|

Price Terms |

FOB, CFR, CIF, EXW |

|

Packing |

Standard sea-worthy package or as required |

Chemical Composition of 410 410S Stainless Steel Coil:

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16.0 -18.0 |

- |

|

202 |

≤0 .15 |

≤L.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤L.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

|

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0 .03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 -15.0 |

16 .0 -1 8.0 |

2.0 -3.0 |

|

321 |

≤ 0 .08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -1 9.0 |

- |

|

630 |

≤ 0 .07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤ 2 .0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤ 0.03 |

0.19 -0. 22 |

0. 24 -0 . 26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤ 0.03 |

≤0.60 |

16.0 -18.0 |

- |

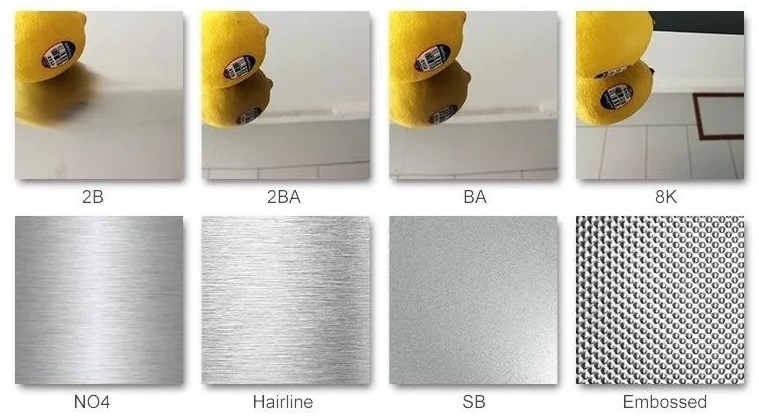

Stainless Steel Surface:

Stainless steel has a variety of surfaces, please contact us for confirmation.

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe. |

Keywords: 410 410S Stainless Steel Coil

Warehouse storage

Packing and delivery

RELATED PRODUCTS

GET A FREE QUOTE

PROVIDE YOU WITH FREE SOLUTIONS

CONTACT US

Tel : +86-17362202101

Email:sales09@zxjtsteel.com

WhatsApp : +86-17362202101

Address:Block A, West Jin Times Central Square, Huaiyin District, Jinan City, Shandong Province